Goldstar Metals Limited proudly operates from an expansive infrastructure that spans 4600 square meters, inclding a meticulously designed built-up area of 28,000 square feet. Our facility is not just large, but purpose-built to handle the entire copper alloy production process with precision and efficiency.

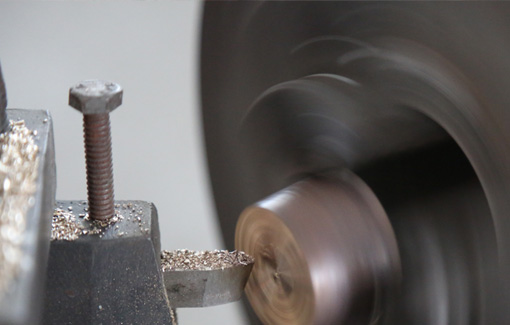

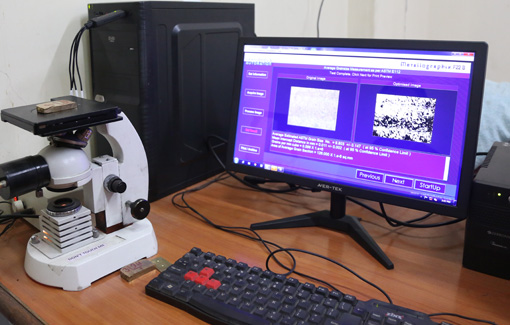

Our well-planned layout allows for streamlined workflows, from raw material handling to final product finishing. Equipped with cutting-edge machinery and advanced production systems, our infrastructure enables us to maintain the highest standards of quality and consistency at every stage of manufacturing. Whether it's casting, extrusion, or finishing, each process is optimized for maximum efficiency, ensuring timely deliveries and unparalleled product quality.