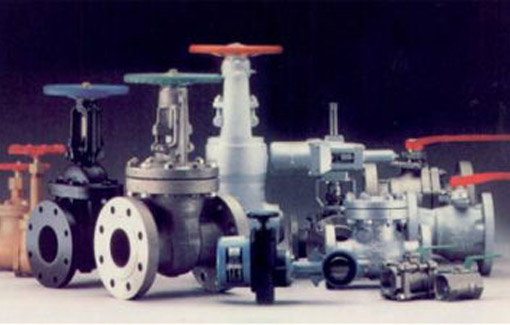

In each of these applicative sectors, Goldstar Metals Limited’s copper alloys contribute to product quality, performance, and longevity. Their unique properties, including corrosion resistance, antimicrobial attributes, electrical conductivity, and durability, make them indispensable materials for these industries. Goldstar Metals Limited is commitment to excellence ensures that its copper alloy products meet the stringent demands of these sectors, fostering trust and long-term partnerships with clients